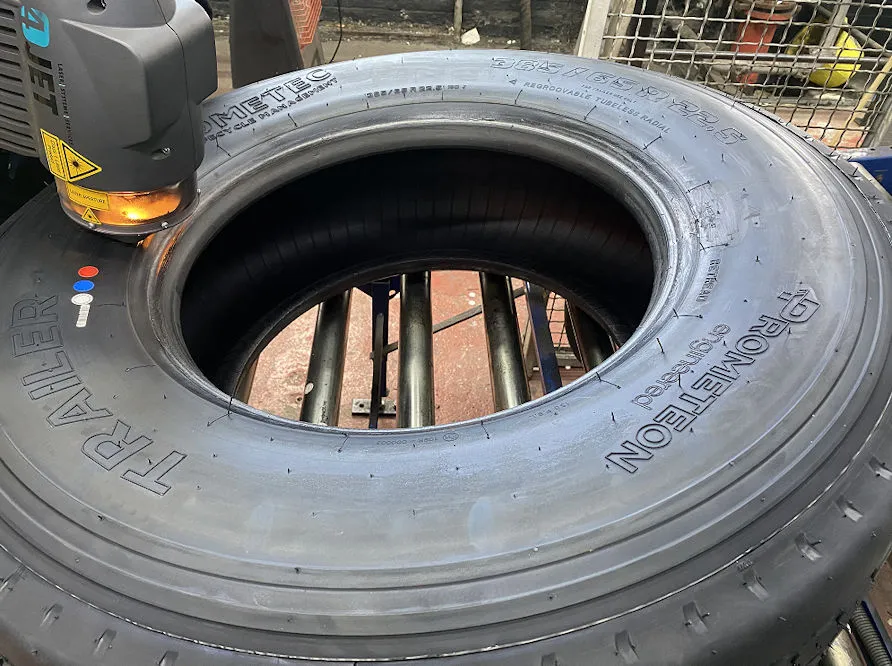

Apollo Tyres is one of India’s largest tyre manufacturers and it confirms the quality of its new tyre casings are suitable for retreading

Apollo says its casings are high quality and suitable for retreading

“Retreadability is a fundamental consideration in the design and development of truck, bus and radial tyres (TBR), and remains a key factor influencing purchasing decisions. Ensuring tyres are retreadable, not only reduces the total cost of ownership for fleet operators, it also minimises their environmental footprint,” states Yves Pouliquen, Vice President, Commercial EMEA, at Apollo Tyres Ltd

He continues to explain that preserving the performance and extending the lifecycle of TBR products is a key priority for Apollo Tyres Ltd. Through ongoing investment in research and development, the company explores innovative ways to maximise tyre longevity – particularly through retreadability. This process involves removing worn tread layers and replacing them with new remoulded layers, while maintaining the tyre’s structural integrity and reliability. All TBR products from Apollo Tyres are compatible with industry-standard retreading methods.

Apollo Tyres offers a comprehensive range of TBR products, which includes the EnduRace and EnduTrax series. Engineered for enhanced durability, consistent performance and a long service life, these product lines deliver exceptional value at an attractive price point. This combination makes Apollo Tyres a compelling choice for fleet operators navigating tight margins.

EnduRace

The EnduRace range forms the backbone of Apollo Tyres’ standard regional and long-distance regional offering, delivering rugged performance, exceptional durability and strong retreadability potential.

For drive-axle applications, the EnduRace RD HD is a long-life drive tyre intended for severe regional use. Engineered for optimum traction and dependable durability across multi-terrain driving, the RD HD features a slow-wearing compound and an optimised footprint that evenly distributes pressure. The tyre’s reinforced casing is 1.5 times the European standard regulatory requirements, further increasing its retread potential and extending its lifespan.

For improved handling and road feel, the EnduRace RD HD features an open tread design, with enlarged groove angles, increased groove volume and modified sipes. This enables the tyre to cut into challenging surfaces and perform year-round, even in winter conditions.

The Apollo EnduRace RD HD+, an enhanced variant of the standard RD HD, contains upgraded materials and a widened shoulder for more uniform tread wear and durability. It improves upon the RD HD with even greater resistance to wear and casing fatigue, outperforming standard durability requirements and maintaining exceptional impact resistance that enables it to be retreaded multiple times.

EnduTrax

The EnduTrax lineup has been engineered as Apollo Tyres’ highly robust series, equipped to best manage high-mileage wear and perform well across extreme on and off-road applications.

The Apollo EnduTrax MA & MA HD is a robust all-wheel tyre designed for vehicles operating in challenging terrains. The tyre contains deep block dual sipes and shoulder notches that provide superior traction and reliable handling, ensuring dependable performance even in the harshest conditions. The tyre features a large contact area for balanced pressure distribution to maximise it performance throughout its life. The reinforced casing supports multiple retreads, offering extended tyre life and reduced total cost of ownership.

The EnduTrax MD is the drive axle tyre in the EnduTrax range maintaining exceptionally durability and for heavy-duty use. Featuring cap-shaped tie bars for automatic self-cleaning, the deep block tread pattern can achieve maximum traction on mud, gravel and loose surfaces. The tyres’ advanced compound lends to high cut, chip and tear resistance, benefiting tread lifespan and subsequent tyre life. The tyres’ structure is also maintained through a highly resistant cushioning between the tread and belts. This additional rubber enhances impact resistance and overall durability.

Pouliquen concludes; “Apollo Tyres remains committed to investing in advanced casing technology and compound development to ensure its TBR portfolio delivers durability from first fit through multiple retread cycles. By aligning innovation with the operational priorities of modern fleets, the company supports improved uptime, sustainability and long-term cost efficiency across the evolving TBR market.”