For Prometeon, retreading is not something that happens at the end of a tyre’s life. It is considered from the very beginning

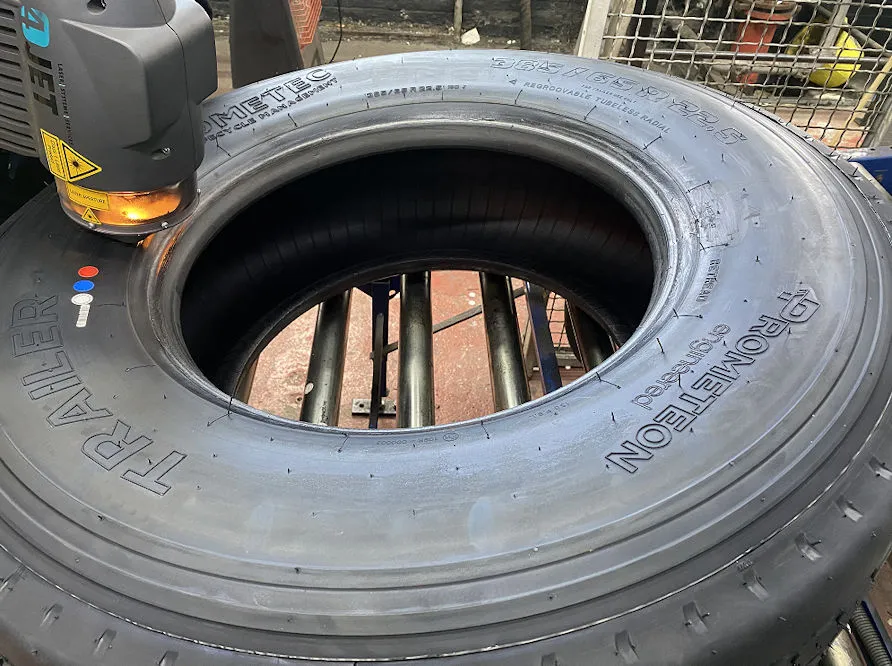

Prometeon offers retreading through Vaculug

“Retreading only works properly if the casing is designed for it from day one,” Ilke Bor, Prometeon’s Marketing Manager UK and Ireland explains. That thinking sits behind its Serie 02 range, where reinforced structures and advanced compound formulations are developed to protect casing integrity across high mileage operations. The focus is on ensuring the casing remains robust enough to deliver consistent performance over successive retread cycles, while retaining the core structural and performance characteristics engineered into the original premium tyre.

In the UK, Prometeon delivers its Pro Retread lifecycle solution in partnership with Vaculug, which is licensed to manufacture Prometec, Prometeon’s approved retread range. Casings are collected and subjected to rigorous inspection processes, including detailed visual checks and non-destructive testing such as shearography. Only those that meet strict structural standards are approved for reuse, typically on drive and trailer axles where retreads provide strong reliability and cost efficiency.

The case for retreading is both technical and economic. Retreads are generally 25 to 30 per cent less expensive than new tyres, but the real benefit lies in reducing cost per kilometre across the full tyre lifecycle. Effective inflation management, regrooving and casing care all directly influence retreadability.

By reusing the casing, around 70 per cent of the raw materials required to manufacture a new tyre are preserved, with each retread avoiding approximately 115 kilograms of CO₂ emissions.

As sustainability reporting, material efficiency and cost scrutiny move higher up the agenda, retreading is increasingly viewed as a strategic component of tyre policy rather than a secondary option.

“With commercial vehicle fleets under pressure to deliver measurable sustainability and cost control, retreading is no longer optional,” Bor concludes. “For the industry, it is a disciplined process built on casing quality, inspection standards and technical partnership. When managed correctly, it protects margins, reduces material use and reinforces the value of the premium casing.”