John Sutch Cranes, who switched exclusively to Michelin in 2020, has praised the durability and reliability of the tyre brand. The company reports that MICHELIN X Crane + tyres are delivering over 20,000km more on average than their previous tyres. This showcases a significant improvement in performance and lifespan.

Michelin Tyres Boost Longevity and Reliability for John Sutch Cranes

John Sutch Cranes adopted a Michelin tyre policy across its mobile crane and heavy haulage fleet. And results have paid off handsomely.

The mobile crane and contract hire specialist was convinced to switch in 2020. This came after testing a trial set of 445/95 R25 MICHELIN X Crane + tyres. These tyres covered more than twice the distance typically achieved by other brands.

Ian Seddon, Service & Engineering Manager at John Sutch Cranes, says, “With other mobile crane all-terrain products that we have used the tyre would start suffering from various irregular wear patterns early in the life of the crane, including tyre delamination, after travelling up to or more than 20,000 to 30,000km, with the sidewalls noticeably an area of weakness.

“The tyres would overheat, suffer blowouts and cause unwanted breakdowns. Tyre loss is enough to massively impact the monetary return from a daily hire. Since fitting MICHELIN X Crane + tyres, we have noticed a remarkably better tyre performance, and the vehicles, irrespective of wheel rim size or lifting equipment capacity, have covered 40,000 to 50,000km with reduced tyre incidents.”

An Extra 20,000km Per Tyre

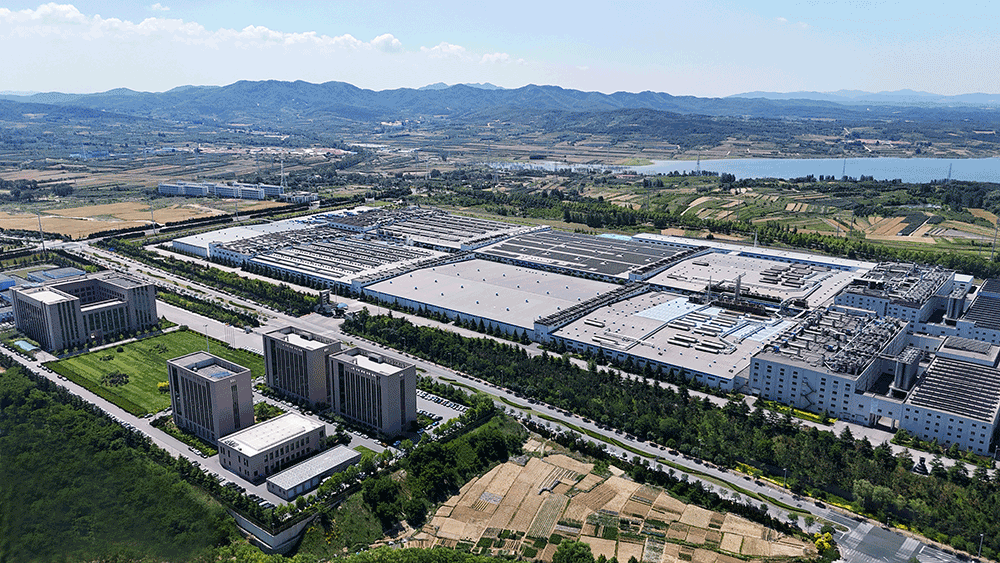

With 38 mobile cranes for hire – including Liebherr, Tadano, Grove and Spierings – operating from two different locations, John Sutch Cranes believes the extra longevity of the Michelin product – conservatively put at an average uplift of 20,000km per tyre compared with rival products – equates to an additional 760,000km of safe, relatively hassle-free travel throughout the fleet each year.

“With a mobile crane, there is always a possibility of an unseen fault with a tyre, i.e. impact occurring from numerous site conditions, especially to the tyre sidewall, along with the noticeable damage to tyres of cuts to cords from hitting kerbs. The tyre creates a heat signature during travel, and when road speed is reduced to negotiate a corner or roundabout, there is a consummate risk of a blowout as the cooling effect of travel is diminished.

“This concern has now been reduced due to the superior build quality of the Michelin product. The X Crane + tyre has delivered a far better all-round performance at all road speeds, keeping the crane’s roadworthy,” says Seddon.

This May, Michelin launched a successor to the MICHELIN X Crane + called the X Crane 2. The tyre features a new tread pattern inspired by Michelin truck tyres to improve braking and grip. A new load and speed index allows 800kg more weight per tyre at 80km/h. The X Crane 2 is also 13.3% more fuel-efficient than its main premium competitor. Results based on tests certified by Dekra at the Ladoux Test Centre in November 2024, thanks to lower rolling resistance.

Ian Fitzpatrick, Michelin Territory Business Manager; Mike Fell, Truck Technical Manager at Michelin Truck & Bus; and Clifford de Jager, Technical Manager for Earthmover and Material Handling Tyres at Michelin have actively supported John Sutch Cranes on its journey.